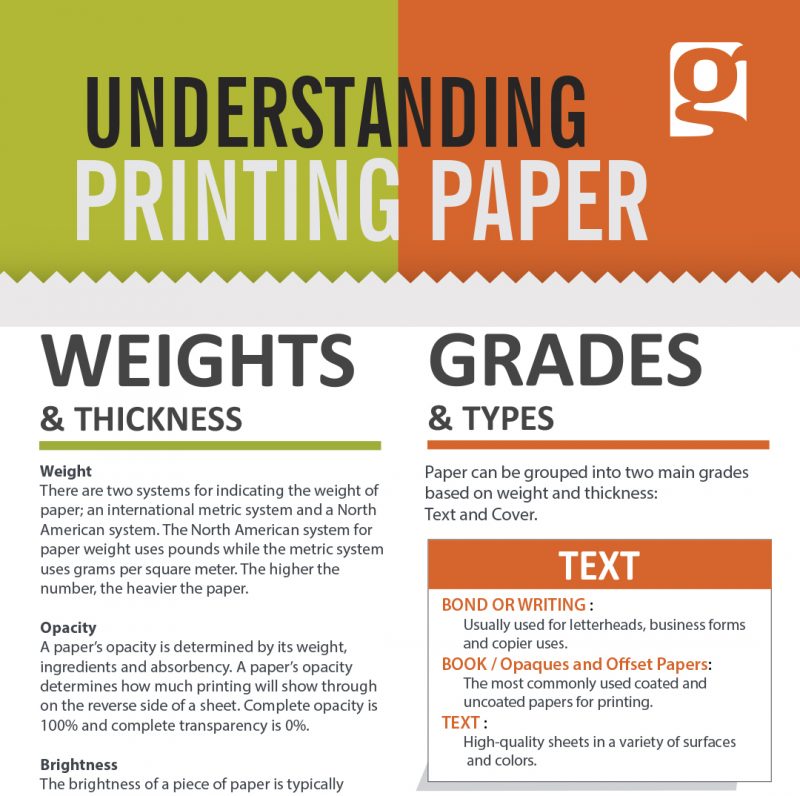

A paper’s opacity determines how much printing will show through on the reverse side of a sheet. OpacityĪ paper’s opacity is determined by its weight, ingredients and absorbency. The caliper (or thickness) of paper is expressed in thousandths of an inch.Ĭase Paper provides a Paper Thickness Chart that can be downloaded here. The higher the weight of the paper, the thicker it is. The three most common weights of bond are 20 lb., 24 lb., and 28 lb., which correlate exactly to offset (uncoated text) weights of 50 lb., 60 lb., and 70 lb., respectively (i.e. The fact that different grades of paper each have different a basis size, makes for a difficult calculation. 500 sheets of paper (or 1 ream) at the basis size (basis size differs depending on grade of paper) are weighed to yield the weight in pounds. In the US however, weight is measured in pounds (#). The metric system is used internationally and is pretty straight forward it measures the weight of a square meter of paper and represents the weight in grams per square meter (GSM). Paper weight can be somewhat confusing, particularly because there are two systems of indicating the weight of paper. There are three main categories that are particularly important: Weight /Thickness/Grain, Coatings, and Finishes. Understanding the characteristics of paper will help you better select the appropriate stock for your project. There are many specialty stocks with various textures which can enhance a project. Ask your account manager for more details. Today there are many papers to choose from for digital printing. Ink and paper technologies are constantly changing. Are you limited to certain types of paper for digital printing? You will need to choose both text and cover stocks if you want the book pages lighter than the cover. If so you will need to think about the coating of the stock. Will you need to be able to write on the paper? You may need to think about the grain of the paper and if the paper will need to be scored to be folded without cracking. The weight or thickness of the paper may be an important consideration. Some questions you need to ask yourself are: Does the piece need some rigidity? The first step is to consider how the piece will be used. They can help guide you through the process and can recommend practical and cost effective options. If you have questions regarding a suitable paper for your project, start by ask your account manager to help you. It’s best to start thinking about the paper choice from the beginning as it can impact many aspect of the printing process from how ink sits on the paper to how it folds. Choosing the correct paper for your project is an important and sometimes crucial decision in your project planning.

0 kommentar(er)

0 kommentar(er)